Services

Reliable. Innovative. Awtad Engineering.

Discover the Future of Industrial Engineering Today!

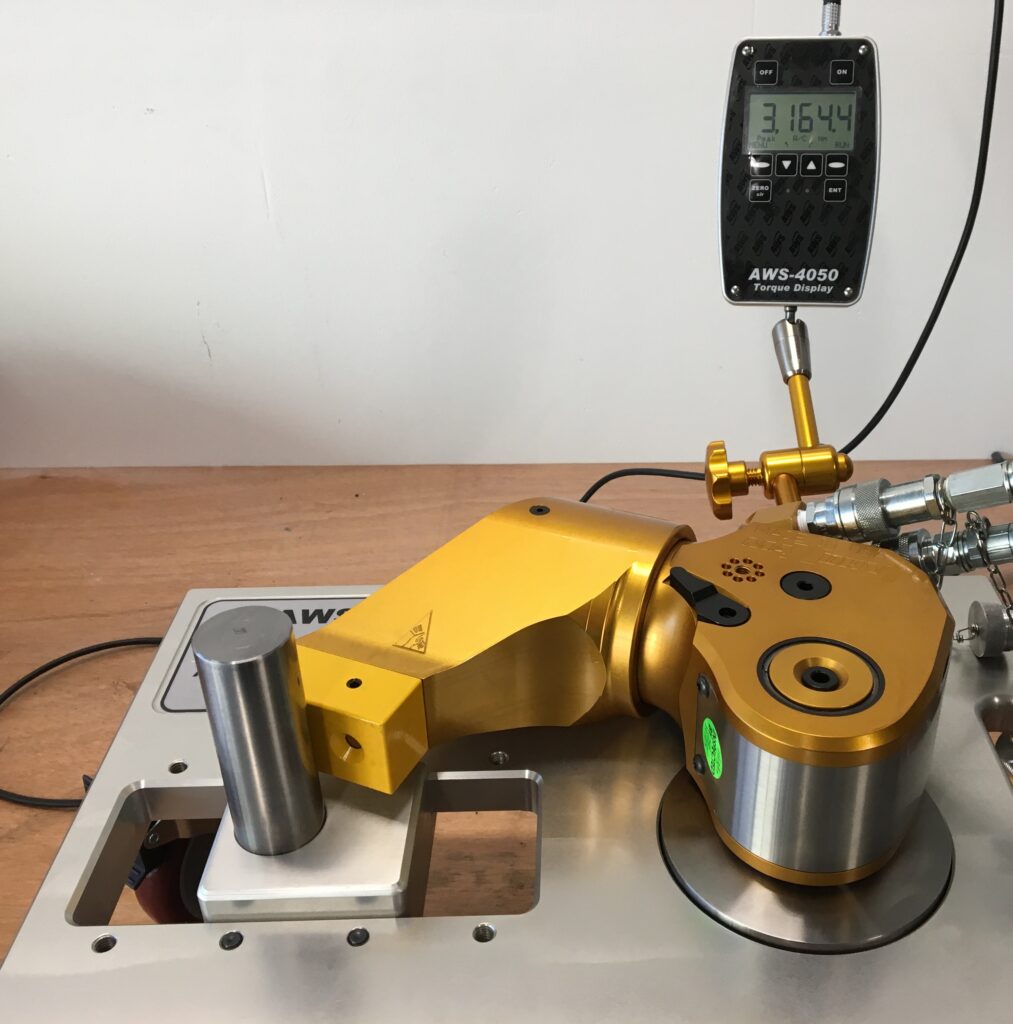

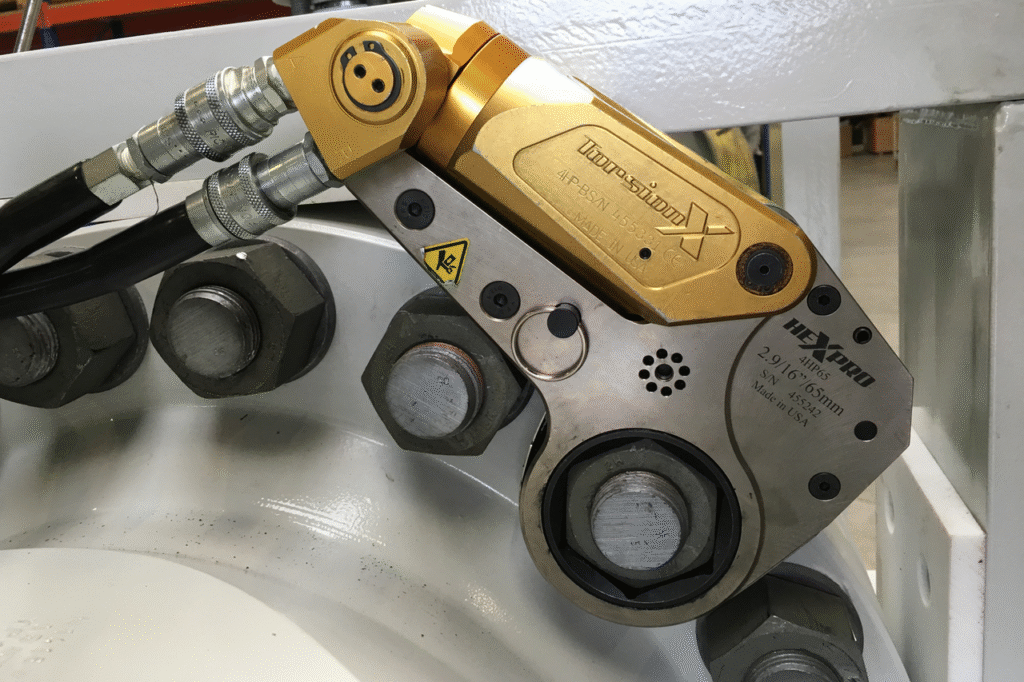

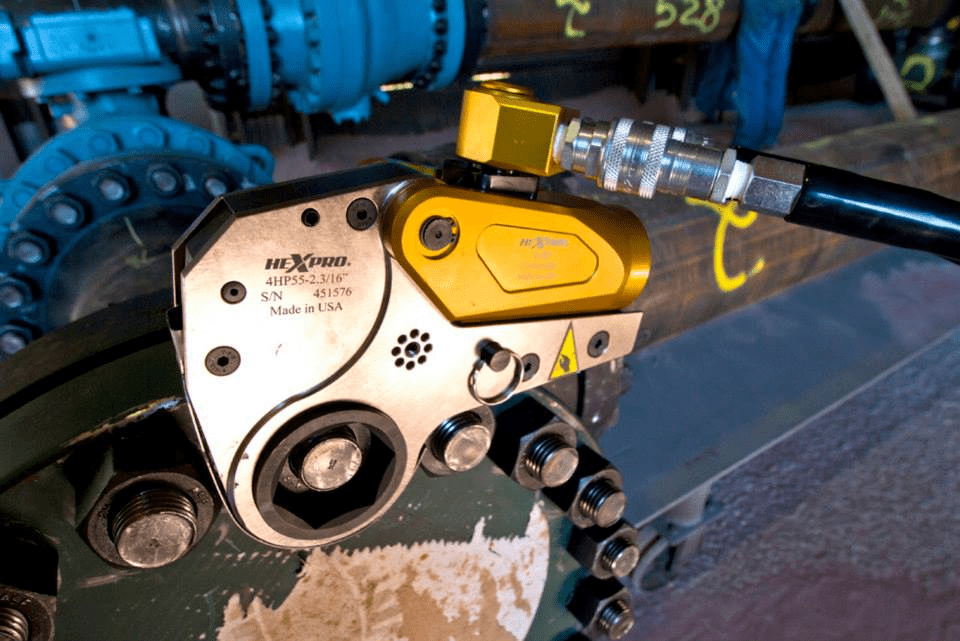

On-site Bolting:

On-site bolting involves the precise assembly and tightening of bolted joints directly at the job location, often under challenging conditions such as limited access, high pressure, or critical alignment requirements. This process is vital for ensuring structural integrity and safety in industries like construction, energy, and manufacturing. Skilled technicians use specialized equipment to apply the correct torque and tension, minimizing the risk of bolt failure and ensuring uniform load distribution across joints. Proper execution of on-site bolting helps prevent downtime, improves reliability, and extends the service life of connected components.

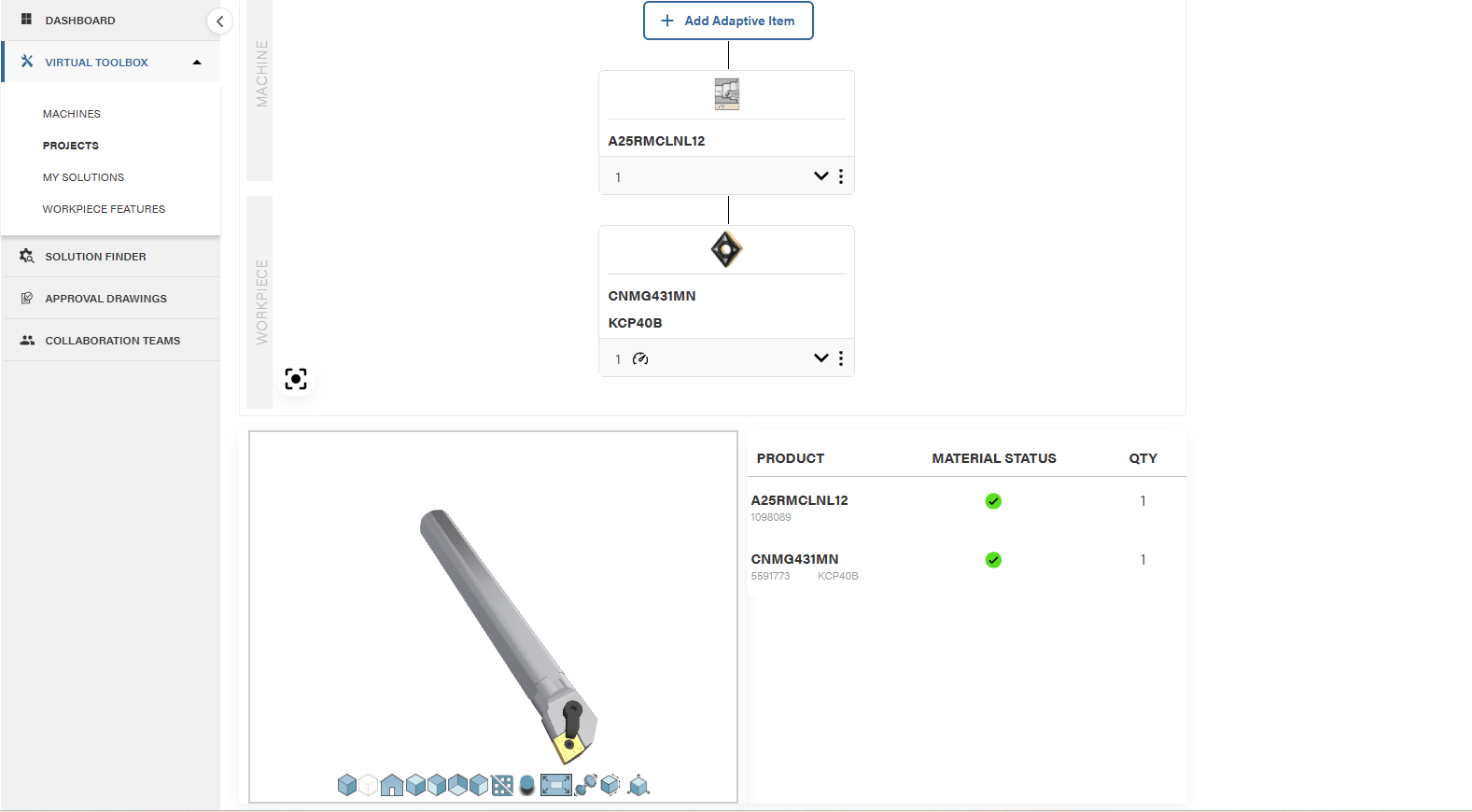

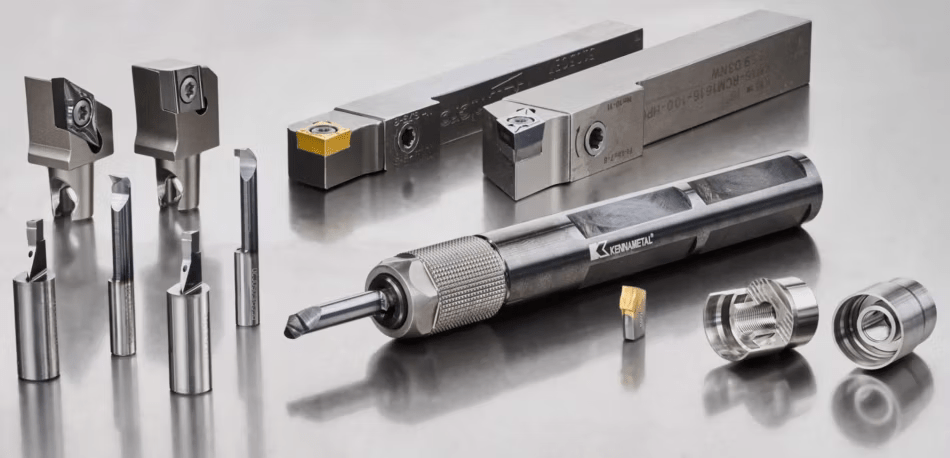

Machining Tools and Cutting Parameters Selection:

Selecting the appropriate machining tools and cutting parameters is critical for achieving optimal material removal, surface finish, and tool longevity in manufacturing processes. This involves choosing the right tool material, geometry, and coatings, as well as setting cutting speed, feed rate, and depth of cut based on the workpiece material and desired outcome. A well-informed selection improves efficiency, reduces tool wear, and minimizes machining defects. Understanding these factors is essential for precision engineering applications, where consistency and accuracy directly affect product performance and production costs.

Awtad offers high-quality hydraulic and bolting tools designed for maximum torque, accuracy, and durability. Our range includes torque wrenches, hydraulic pumps, tensioners, and bolting accessories to handle even the most demanding industrial applications. Whether you’re in oil & gas, construction, or heavy machinery, our tools deliver unmatched reliability and efficiency.

Bolting tools maintenance and calibration

Coming soon